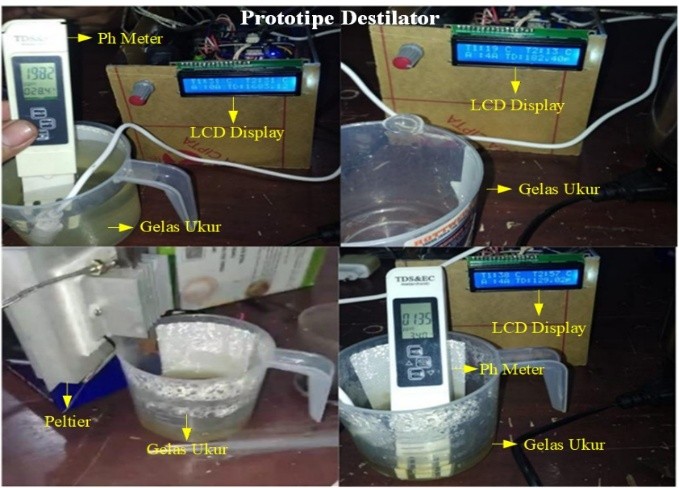

Sistem Kontrol Suhu Pada Destilator Untuk Mengukur Kadar Air Limbah Pabrik Udang Berbasis Arduino

DOI:

https://doi.org/10.63440/jef.v2i2.119Keywords:

Control Design, Distilator, Temperature, Wastewater, TDS SensorAbstract

This paper discusses the design and temperature control system for shrimp factory wastewater distillation. During the distillation process, wastewater is heated to condense and separate the resulting water vapor. Therefore, a temperature control system is proposed to ensure efficiency. The effectiveness of temperature control in the distillation process is assessed based on changes in temperature. Changes in initial and final temperatures were observed in the distillation process using 50ml-250ml samples and a temperature variation of 34°C–101°C. Test results showed that a 50ml sample reached a maximum temperature of 82°C, producing 9ml of condensate. A 100ml sample, with a maximum temperature of 84°C, produced 19ml of condensate. A 150ml with a maximum temperature of 92°C. Producing 60 ml of condensate, the 200 ml sample reached a maximum temperature of 85°C, producing 60 ml of condensate, and the 250 ml sample reached a maximum temperature of 101°C, producing 60 ml of condensate. The initial TDS value for the 50–250 ml samples remained constant at 1,683 ppm. After distillation, the TDS values for each sample were 319 ppm for the 50 ml sample, 671 ppm for the 100 ml sample, 93 ppm for the 150 ml sample, 86 ppm for the 200 ml sample, and 129 ppm for the 250 ml sample. The contribution of the research is that the control system can reduce the impact of waste on industry by regulating the temperature on the Peltier.

Downloads

References

W. Fitriani and B. Hariyanto, “Dampak Pembuangan Limbah Industri Pengolahan Udang Terhadap Kualitas Air Di Aliran Sungai Kecing Desa Cebolek Kidul Kecamatan Margoyoso Kabupaten Pati,” Swara Bhumi, vol. 2, no. 1, 2020. https://ejournal.unesa.ac.id/index.php/swara-bhumi/article/view/34067

N. Pushpalatha, V. Sreeja, R. Karthik, and G. Saravanan, “Total Dissolved Solids and Their Removal Techniques,” Int. J. Environ. Sustain. Prot., vol. 2, no. 2, pp. 13–20, 2022, doi: https://doi.org/10.35745/ijesp2022v02.02.0002

P. A. Hawi Etana Debela, Forimsa Bidira, “Removal of BOD, TDS, and Phosphate from Industrial Parks Wastewater by Using a Combined Sono-Pulsed Electrocoagulation Method,” Scientific African, vol. 28 2025. Doi: https://doi.org/10.1016/j.sciaf.2025.e02741

D. A. M. N. Efendi, A. A. Ramandani, D. Cendekia, and W. Hanifah, “Industrial wastewater treatment using venture injector type Micro-bubble aeration as a reduction of dissolved Iron (Fe2+) levels,” J. Nat. Sci. Math. Res., vol. 9, no. 2, pp. 91–101, 2023, doi: https://doi.org/10.21580/jnsmr.2023.9.2.17594

R. D. Prasetya and P. S. A. Sitogasa, “Analisis Kualitas Buangan Instalasi Pengolahan Limbah Cair Industri Daur Ulang Plastik Di Jawa Timur,” J. TESLINK Tek. Sipil dan Lingkung., vol. 7, no. 1, pp. 193–205, 2025, doi: https://doi.org/10.52005/teslink.v1i1.420

P. Nirwana and L. Legasari, “Analisis Kadar Total Dissolved Solid (TDS) pada Air Limbah Industri Menggunakan Metode Gravimetri,” Sains J. Kim. dan Pendidik. Kim., vol. 13, no. 2, pp. 132–135, 2025, doi: https://doi.org/10.36709/sains.v13i2.80

G. A. Pradelia, H. P. Buwono, and I. K. B. Artha, “Penurunan Nilai Turbidity Dan Total Suspended Solid Pada Limbah Cair Industri Additive Chemical Construction Menggunakan Koagulan Tawas,” DISTILAT J. Teknol. Separasi, vol. 11, no. 1, pp. 121–130, 2025, doi: https://doi.org/10.33795/distilat.v11i1.6926

M. Muliyadi and I. S. Sowohi, “Perbandingan Efektifitas Metode Elektrokoagulasi dan Destilasi Terhadap Penurunan Beban Pencemar Fisik Pada Air Limbah Domestik,” J. Kesehat. Lingkung. Indones., vol. 19, no. 1, p. 45, 2020, doi: https://doi.org/10.14710/jkli.19.1.45-50

Y. A. Pujiastuti, “Pengaruh Suhu Dan Waktu Operasi Pada Proses Destilasi Untuk Pengolahan Aquades Di Fakultas Teknik Universitas Mulawarman,” J. Chemurg., vol. 1, no. 1, p. 31, 2021, doi: https://doi.org/10.30872/cmg.v1i1.1137 .

A. Dasa Novowan, M. Miftah, and W. Kusuma, “Scada Pada Proses Destilasi Dengan Pengendalian Suhu Menggunakan PID,” Elprosys J. Sist. Kelistrikan, vol. 11, no. 1, pp. 56–61, 2024, doi: https://doi.org/10.33795/elposys.v11i1.4963

D. & Martias, “Optimisasi Pengukuran dan Pengendalian Suhu pada Furnace Industri Menggunakan Termokopel Tipe K dan Sistem PID,” vol. 5, no. 2, pp. 67–70, 2024. doi: https://doi.org/10.31294/insantek.v5i2.5413

Afrizal Matondang, “Rancang Sensor Thermocouple Type K Untuk Alat Pengukur Suhu Tungku Heat Treatment,” Thesis 2022. http://repository.umsu.ac.id/

Y. Abdelaziz, M. Hammam, F. Megahed, and E. R. Qamar, “Characterizing Drift Behavior in Type K and N Thermocouples After High Temperature Thermal Exposures,” J. Adv. Res. Fluid Mech. Therm. Sci., vol. 97, no. 1, pp. 62–74, 2022, doi: https://doi.org/10.37934/arfmts.97.1.6274

B. E. Pratama, G. A. Pauzi, sri wahyu suciyati, and amir upriyanto, “Heating Rate Control in Electric Furnace with SSR and K-Type Thermocouple Using Arduino Uno Atmega 328P,” J. Energy, Mater. Instrum. Technol., vol. 4, no. 1, 2023, doi: https://doi.org/10.23960/jemit.v4i1.117

D. Rahadian Aji Muhammad, P. Darmadji, Y. Pranoto, P. Studi Ilmu dan Teknologi Pangan, F. Pertanian, and J. Teknologi Pangan dan Hasil Pertanian Fakultas Teknologi Pertanian, “Effect of Distillation Temperature and Stage of Condenser on Sensory Characteristic of Liquid Smoke Distillate,” J. Teknol. Has. Pertan., vol. IV, no. 2, p. 108, 2011. https://rahadiandimas.staff.uns.ac.id/?p=619

M. Yusfi, F. Gandi, and H. S. Palka, “Analisis Pemanfaatan Dua Elemen Peltier Pada Pengontrolan Temperatur Air,” Spektra J. Fis. dan Apl., vol. 2, no. 1, pp. 9–14, 2017, doi: https://doi.org/10.21009/spektra.021.02

S. P. Prakash, V. Nithyalakshmi, G. Sujatha, and R. M. Nirmal, “Experimental Study on Comparison of Peltier Module TEC1 12706 And TEC1 12715 S.,” Int. J. Appl. Eng. Technol., vol. ISSN, pp. 9–14, 2021, [Online]. Available: http://www.cibtech.org/jet.htm

I. Sormin, I. Gunanya, and I. Aviantara, “Kinerja Kotak Pendingin (Cooler Box) Berpendingin TEC1-12715 Pada Beberapa Beban Pendinginan,” J. Beta (Biosistem Dan Tek. Pertanian), vol. 11, no. 1, pp. 29–37, 2023, [Online]. Available: http://ojs.unud.ac.id/index.php/beta

T. U. G. Manik, T. B. Sitorus, and F. Sembiring, “Kinerja Sistem Kotak Pendingin Peltier Tenaga Surya Untuk Penyimpanan Sayur dan Buah,” Rotasi, vol. 20, no. 4, p. 214, 2019, doi: 10.14710/rotasi.20.4.214-220.

H. A. Calvin, Samar, “Studi Eksperimental Solar Cold Energy Storage Dengan penambahan PCM Dan Tanpa PCM,” J. Din., vol. 10, no. 1, pp. 39–47, 2022. https://doi.org/10.32734/dinamis.v10i1.9086

L. Laila et al., “Perancangan Total Dissolved Solids (TDS) Monitoring pada air boiler Berbasis Mikrokontroler di Pabrik Kelapa Sawit Naga Sakti,” 2021. https://repository.itsb.ac.id/id/eprint/528/

T. Tarigan, “Analisis dan Aplikasi Sensor pH, Sensor TDS, Sensor NTU, dan Sensor Suhu dalam Pengukuran Kualitas Air,” vol. 11, no. 5, pp. 5512–5514, 2024. https://openlibrarypublications.telkomuniversity.ac.id/index.php/engineering/article/view/26348

S. F. Karo Karo, D. Darianto, and M. Idris, “Analisis Efektivitas Perpindahan Panas Kondensor pada Proses Destilasi Daun Serai Wangi,” J. Ilm. Tek. Mesin Ind., vol. 2, no. 1, pp. 31–40, 2023, doi: https://doi.org/10.31289/jitmi.v2i1.1951

F. I. Pasaribu, A. K. Hasibuan, N. Evalina, E. S. Nasution, and S. Suherman, “Analisa Penggunaan Surya Panel Polikristal 240 WP Sebagai Kinerja Destilator Air Laut,” RELE (Rekayasa Elektr. dan Energi) J. Tek. Elektro, vol. 4, no. 2, pp. 90–99, 2022, doi: https://doi.org/10.30596/rele.v4i2.9530

I. Nurhayati et al., “Optimasi Proses Distilasi Multikomponen untuk Pemisahan Alkohol,” J. Majemuk, vol. 3, no. 2, pp. 206–218, 2024. https://jurnalilmiah.org/journal/index.php/majemuk/article/view/674

H. Isman, I. Rupee Wardani, and D. Sari, “Gambaran Pencemaran Limbah Cair Industri Tambak Udang Kualitas Air Laut di Pesisir Pantai Lombeng,” J. Pendidik. dan Konseling, vol. 4, no. 3, pp. 1349–1358, 2022. http://dx.doi.org/10.25157/ma.v11i1.17165

Q. N. Komalasari and I. W. Abida, “Pengaruh Pembuangan Limbah Cair Industri Pembekuan Udang Terhadap Kualitas Air Sungai Di Kabupaten Sidoarjo,” Juv. Ilm. Kelaut. dan Perikanan., vol. 2, no. 3, pp. 202–211, 2021, doi: https://doi.org/10.21107/juvenil.v2i3.11753 .

N. T. Wahyudi, F. F. Ilham, I. Kurniawan, and A. S. Sanjaya, “Rancangan Alat Destilasi untuk Menghasilkan Kondensat dengan Metode Distilasi Satu Tingkat,” J. Chemurg., vol. 1, no. 2, p. 30, 2018, doi: https://doi.org/10.30872/cmg.v1i2.1142

S. Asfiyah, “Modifikasi Dean Stark Upaya Efisiensi Proses Distilasi Uap Minyak Biji Pala Dalam Praktikum Kimia Organik,” Indones. J. Lab., vol. 2, no. 1, p. 10, 2020, doi: https://doi.org/10.22146/ijl.v2i1.54161

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Mahindra Abhiyaksa, Adi Mulyadi, Widhi Winata Sakti (Author)

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.